|

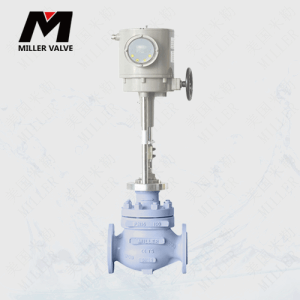

- 品牌:米勒

- 货号:F202405024

- 价格: ¥9500/台

- 发布日期: 2024-05-21

- 更新日期: 2025-06-24

| 外型尺寸 | DN16-DN500 |

| 货号 | F202405024 |

| 品牌 | 米勒 |

| 用途 | 控制流量介质 |

| 型号 | MILLER |

| 工作压差 | PN0.5~42.0MPa |

| 制造商 | 米勒 |

| 压力环境 | 常压 |

| 介质温度 | +450℃ |

| 驱动方式 | 电动 |

| 适用介质 | 其他 |

| 是否进口 | 是 |

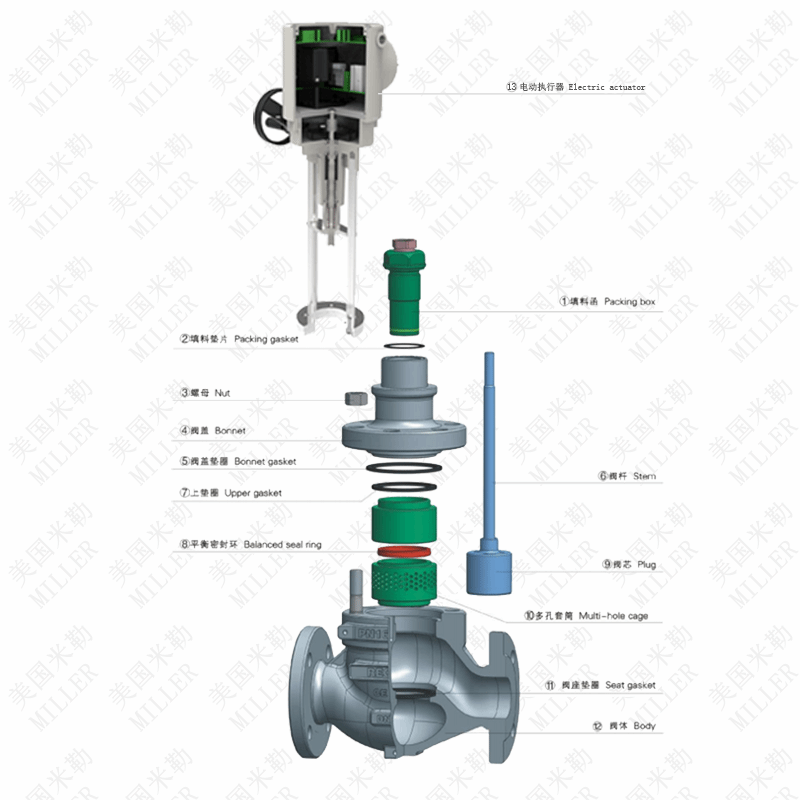

电动比例调节阀通过电动执行器 控制阀芯位置,实现对流体流量的连续、精细调节。其响应迅速、调节精度高,适用于各种需要精准流量控制的工业应用,如化工、暖通空调、水处理等。电动比例调节阀结构紧凑、操作简便,且具有良好的密封性能和长寿命。

电动比例调节阀的技术参数

-

公称压力(PN):1.6MPa至4.0MPa,适用于中高压流体系统。

-

公称通径(DN):DN15到DN300,适合不同管道口径需求。

-

适用温度:为-20℃至+200℃,适应广泛的工业温度范围。

-

适用介质:水、蒸汽、油品、气体及其他液体介质。

-

阀体材料:铸钢、不锈钢、合金钢等。

-

密封材料:PTFE、硬质合金、EPDM等。

-

操作方式:电动执行器控制,支持模拟信号(如4-20mA、0-10V)输入。

-

电源电压:AC220V、AC380V、DC24V。

-

流量特性:括直线、等百分比或快开。

-

连接方式:法兰连接、螺纹连接或焊接连接。

-

控制精度:高精度位置反馈和调节机制,确保流量的精准控制和系统稳定性。

| DN | L | H | H1 | ΦA | 重量 weightkg | ||||||

| PN16 | PN40 | PN64 |

普通 Ordinary |

高温High | PN16 | PN40 | PN64 | PN16 |

PN40 PN64 |

||

| 25 | 184 | 197 | 210 | 503 | 653 | 57 | 70 | 260 | 15 | 19 | |

| 40 | 222 | 235 | 251 | 648 | 813 | 75 | 85 | 290 | 26 | 35 | |

| 50 | 254 | 267 | 286 | 650 | 820 | 82 | 90 | 30 | 40 | ||

| 65 | 276 | 292 | 311 | 752 | 932 | 92 | 102 | 34 | 53 | ||

| 80 | 298 | 317 | 337 | 764 | 949 | 100 | 107 | 42 | 65 | ||

| 100 | 352 | 368 | 394 | 782 | 992 | 110 | 117 | 125 | 52 | 86 | |

| 150 | 451 | 473 | 508 | 1077 | 1337 | 142 | 150 | 172 | 360 | 152 | 206 |

| 200 | 600 | 650 | 1097 | 1357 | 170 | 187 | 207 | 220 | 280 | ||

| 250 | 730 | 775 | 1240 | 1560 | 202 | 225 | 235 | 423 | 470 | ||

| 300 | 850 | 900 | 1271 | 1591 | 230 | 257 | 265 | 663 | 735 | ||

美国Miller阀门是一家国际性的专业阀门公司,美国米勒阀门公司(USA MILLER VALVE GATE INC)企业总部位于美国特拉华州,致力于生产、设计研发高品质通用阀门和控制阀门。是进口调节阀,进口球阀,进口电磁阀,进口蝶阀,进口减压阀等产品研发、设计、生产、销售于一体的企业。我们拥有强大的技术 队伍,企业总部位于美国特拉华州。经过几十年来兢兢业业的工程师不断开发及研究,获得一个又一个认证,在 一百多个国家设有办事处和代理商。MILLER阀门现采用 先进的加工设备、生产工艺,检测仪器,经过严格的质量检验,所生产的产品达到 水平。

米勒工厂目前拥有加工中心、大型立车、镗床、磨床、等离子堆焊、全自动气体保护焊、水帘环保自动喷漆流水线等生产设备。检测设备方面拥有光谱仪、硬度计、 试验机、拉伸冲击试验机、全自动阀门液压测试仪、超声波测厚仪等。合格率达 。产品广泛应用于:石化系统,电力系统,冶金系统,水利系统等。

Miller Valve is an international professional valve company, with its headquarters located in Delaware, USA. Miller Valve INC is committed to producing, designing, and developing high-quality universal valves and control valves. We are an enterprise that integrates the research and development, design, production, and sales of imported regulating valves, imported ball valves, imported solenoid valves, imported butterfly valves, imported pressure reducing valves, and other products. We have a strong team of technical experts and our corporate headquarters is located in Delaware, USA. After decades of dedicated engineers continuously developing and researching, we have obtained one certification after another and have offices and agents in over 100 countries worldwide. MILLER valves now use world leading processing equipment, production processes, and testing instruments. After strict quality inspection, the products produced have reached a leading level.

The Miller factory currently has production equipment such as machining centers, large vertical lathes, boring machines, grinding machines, plasma welding, fully automatic gas shielded welding, and environmentally friendly automatic spray painting assembly lines. In terms of testing equipment, we have spectrometers, hardness testers, universal testing machines, tensile impact testing machines, fully automatic valve hydraulic testers, ultrasonic thickness gauges, etc. The qualification rate reaches . The product is widely used in petrochemical systems, power systems, metallurgical systems, water conservancy systems, etc.